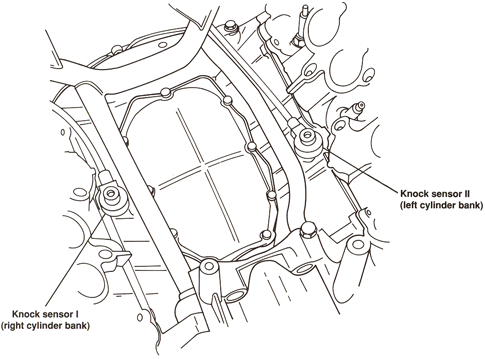

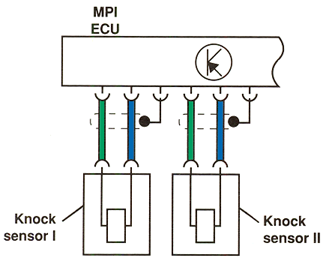

ComponentsF60: Idle switch G4: Crankshaft Position Sensor G6: Fuel pump G28: Engine Speed Sensor G39: Oxygen sensor I G40: Hall Sensor G61: Knock sensor I G62: Engine Coolant Temperature (ECT) sensor G66: Knock sensor II G69: Throttle valve potentiometer G70: Mass Air Flow (MAF) sensor G98: Exhaust Gas Recirculation (EGR) temperature sensor G108: Oxygen sensor II J176: Fuel pump relay J192: Engine Control Module (ECM) N: Ignition coil for cylinders 1 and 6 N18: EGR frequency valve N30: Fuel injector, cylinder 1 N31: Fuel injector, cylinder 2 N32: Fuel injector, cylinder 3 N33: Fuel injector, cylinder 4 N71: Idle Air Control (IAC) valve N80: EVAP carbon canister frequency valve N83: Fuel injector, cylinder 5 N84: Fuel injector, cylinder 6 N122: Power stage for ignition coils N128: Ignition coil for cylinders 2 and 4 N156: Intake manifold change-over valve N158: Ignition coil for cylinders 3 and 5 P: Spark plug connector (6x) Q: Spark plug (6x) S17: Fuse for G6 S19: Fuse for diagnostic connector S64: Circuit breaker for N158, N128, and N S72: Circuit breaker for N30, N31, N32, N33, N83, and N84 S73: Circuit breaker for G39, G108, N18, N80, and N156 S74: Circuit breaker for G70 and G74 Additional SignalsB8: Throttle valve signal (not pictured) B9: Road speed signal (not pictured) B10: Engine speed signal (not pictured) B11: Fuel consumption signal (not pictured) B12: Shift lever position signal (not pictured) B13: Shift point signal (not pictured) C10: A/C compressor signal (not pictured) C12: Diagnostic signal for Rapid Data (K circuit) C13: Diagnostic signal for Rapid Data (L circuit) C14: Flash code signal |

|

|

|